Our Reason is Water.

Advanced Drainage Systems leads the industry with a comprehensive and sustainable suite of products proven to work.

America's Most Responsible Company in 2024

ADS has been named by Newsweek as one of America's Most Responsible Companies in 2024. For the 2nd consecutive year, we are recognized for our commitment to environmental, social and corporate governance efforts.

Read More

2023 Harris Poll Survey Results

The Harris Poll conducted a survey on behalf of Advanced Drainage Systems, Inc. exploring public perceptions on water management in the U.S.

Learn More

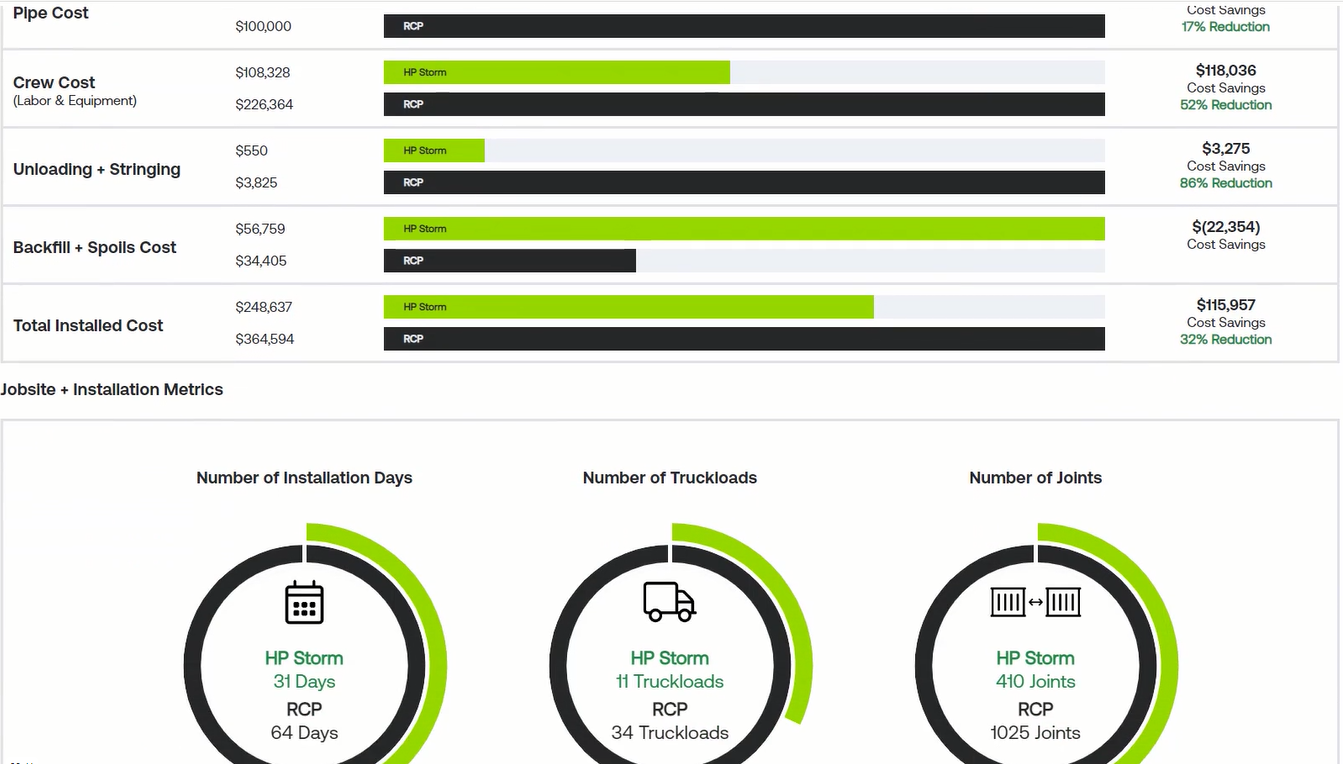

Introducing the Pipe Value Tool

Create reports to calculate and compare the total installed cost differences between ADS dual wall pipe products and the competition.

Start Using NowThe Lifecycle of a Raindrop™

From the moment rain enters our drain until we safely return it back to its natural environment, we take the responsibility of managing the precious resource of water very seriously.

Learn About the Lifecycle of a Raindrop

Engineered for the if, ready for the when.

Everyday stressors are just as significant as severe weather events. Our resilient stormwater management solutions are designed to handle both, providing long-term value and rapid recovery when time is of the essence.

Learn MoreDid you know?